The ins and outs of textile biodegradability

How textiles biodegrade, what influences the process and the differences between biodegradable and bio-based synthetics

Welcome to another issue of The Crisps – your newsletter on anti-greenwashing and honest fashion communication. You can support us by subscribing to a free or pro subscription, liking, sharing, or commenting on our posts.

It is often hailed as a game-changer for our industry. But does biodegradability hold up to the promise? If you’ve been reading The Crisps for a while, you’ll know that our answer is never simply yes or no because we preach the complexity of the fashion and textile industry. It’s not any different for biodegradability.

While we originally wanted to focus mostly on biodegradable synthetics, we decided to look at the topic in a bigger scope. Because we have to understand the basics, the differences in materials, how they biodegrade, and how the process works. So this issue is PACKED with insights into the processes of textile biodegradability, testing methods, composting vs. biodegradation, and the differences between biodegradable and bio-based synthetics. And if we talk about biodegradability, we also have to talk about appropriate recycling and waste disposal infrastructures. Are you ready?

Before we dive in, we have two specials for you!

Firstly, this issue’s pro section will be open to read for everyone. We’re clearing up many misconceptions in our pro section that we don’t want to keep behind a paywall

Secondly, this issue is only possible because we had great support from Julia Eckert. Julia is an environmental engineer with a focus on recycling technology. She completed her master's degree at RWTH Aachen University and worked at the Textile Institute Aachen among other stops. Currently, Julia works at a workwear manufacturer where she assesses material and packaging solutions to find the best fitting and practical solution. Biodegradability is often a part of it. We’re happy to have her expertise in this issue!

What to expect in today’s pro section:

When we say this issue is packed, we mean it. Here’s what you’ll find in the pro section.

Are biodegradable plastics the solution for our industry’s waste problem?

Bio-based vs. biodegradable plastics

Why bio-based plastics are not always biodegradable

Why integrating biodegradable plastics into recycling streams is not as easy as it may sound

Common claims about the biodegradability of synthetics and why they are wrong

All the best,

Tanita, Lavinia & Julia

First up, the most important information for the entire issue! The origin of the raw material (whether based on fossil or renewable biological materials) is irrelevant to biodegradability. The decisive factor as to whether a material is biodegradable is solely its chemical structure. A material is only biodegradable when microorganisms and fungi (or their enzymes) can completely metabolize it.

Which factors influence the biodegradation of textiles?

Environmental Conditions: Temperature, humidity, presence of oxygen, and microbial activity significantly impact the rate of degradation. Biodegradation happens faster in warm, moist, and oxygen-rich environments.

Fiber Treatment: Many textiles are treated with dyes, flame retardants, water repellents, or antimicrobial agents, which can hinder or slow down biodegradation.

Fiber Blends: Blended fabrics, such as those made from a mix of natural and synthetic fibers (e.g., cotton-polyester), complicate biodegradability. The natural fibers may break down more quickly, leaving behind synthetic remnants.

Biodegradability is utilized in various technical processes:

Composting: For example, biodegradable plastics can be completely decomposed by microorganisms into carbon dioxide (CO2), water (H2O), mineral salts and biomass (aka humus). This works in the presence of oxygen and is therefore referred to as aerobic breakdown.

Fermentation: In fermentation, the breakdown takes place in the absence of oxygen. The main products are carbon dioxide (CO2) and methane (CH4).

Composting vs. biodegradation: Industrial vs. home composting

The terms "compostable" and "biodegradable" are often used interchangeably, but they refer to different processes with distinct outcomes. Let’s take plastics as an example: Compostable plastics are a subset of biodegradable plastics, but not all biodegradable plastics are compostable.

There are two composting settings:

Industrial composting facilities provide the high temperatures (50–70°C), moisture levels, and microbial activity necessary for the rapid breakdown of compostable plastics. PLA, for example, is compostable under these conditions but is unlikely to break down in a home compost pile, where temperatures are much lower. Industrial composting also ensures that plastics degrade within a defined time frame, usually less than six months.1

At home composting temperatures rarely exceed 30°C and microbial activity is lower than in industrial settings. While many natural fibers can still decompose under these conditions, it’s a more challenging environment for plastics. Some bio-based and biodegradable plastics, like certain starch-based materials, are designed to break down in home composting systems, but this process can take much longer.

As biodegradability has many facets and is also interpreted differently, a large number of different test methods have been developed that can prove biodegradability under certain conditions. Some of these test methods now even have concrete standards:

in the US (ASTM standards)

Europe (EN standards)

globally valid standards (ISO standards)

So if you want to use a biodegradable textile and report correctly on its biodegradability (note: important to communicate your green claims correctly!), it is advisable to ask for test certificates according to recognized standards or to have institutes carry out tests. The key, of course, is to select the right or most appropriate test for your material and product.

The Hohenstein Test Institutes carries out biodegradability tests based on the following standards, among others:2

DIN EN ISO 11721-1: Textiles - Determination of the resistance of cellulosic textiles to micro-organisms; Soil inertness test - Part 1: Proof of a rot-inhibiting finish

DIN EN ISO 846: Plastics - Determination of the effect of microorganisms on plastics

The test determines, for example, how quickly the textile degrades by microorganisms in the soil where the so-called mass loss over a certain period of time is determined. Furthermore, the ecotoxicological impact on the environment is tested with the help of cress and earthworm tests.3 4

Textile fibers can be broadly classified into natural and man-made (synthetic) fibers. Their biodegradability depends on their chemical structure and environmental conditions.5 Let’s look at it in more detail.

1. Natural Fibers

Natural fibers are derived from plants, animals, or minerals, and they are generally more biodegradable than synthetic fibers because they are composed of organic materials. However, the rate and extent of biodegradation depend on environmental factors such as moisture, temperature, microorganisms, and the presence of oxygen.

Plant-Based Fibers

Cotton: Cotton is made of cellulose, a natural polymer that microorganisms can break down fairly easily. Under optimal conditions (warm, moist, and oxygenated environments), cotton can biodegrade in a few months to a year. However, treatments like dyeing, bleaching, or adding water-repellent finishes can slow down this process.

Linen (Flax): Like cotton, linen is made of cellulose and biodegrades relatively quickly in ideal conditions. Its structure is denser than cotton, so it may take slightly longer to decompose, but it typically breaks down within months to a year.

Jute: Also composed of cellulose, jute biodegrades similarly to cotton and linen, though environmental conditions and treatments affect its breakdown.

Animal-Based Fibers

Wool: Wool is a protein fiber made of keratin, which is slower to biodegrade compared to cellulose fibers. In composting or soil environments with the right microbes, wool can biodegrade within a few years, though untreated wool decomposes faster than treated wool (for example dyed or chemically treated).

Silk: Like wool, silk is a protein fiber, primarily made of fibroin. Under favorable conditions (such as compost or soil), silk can degrade within a few months to a few years, depending on treatments applied during textile production.

2. Man-Made (Synthetic) Fibers

Synthetic fibers are created through chemical processes, and their biodegradability varies significantly depending on their origin (whether they're bio-based or petroleum-based) and composition.

Semi-Synthetic Fibers (Regenerated Cellulose Fibers)

These fibers are made from natural cellulose but are chemically processed.

Viscose/Rayon: These fibers are made from plant-based cellulose but undergo heavy chemical processing. Despite this, viscose is relatively biodegradable, usually decomposing within a few months to a year, as microorganisms can still break down the cellulose in it.

Lyocell (Tencel™): Like viscose, lyocell is made from wood pulp, but it is processed using more eco-friendly solvents. It is biodegradable and typically breaks down within months under the right conditions.6

Synthetic Fibers (Petroleum-Based)

Petroleum-based synthetic fibers do not readily biodegrade because they are made of long chains of polymers that microorganisms cannot easily digest.

Polyester: One of the most common synthetic fibers, polyester is made from petrochemicals like polyethylene terephthalate (PET). Polyester is highly resistant to biodegradation and can take hundreds of years to decompose in landfills. It breaks down more slowly due to its chemical stability and high resistance to microbial attack.

Nylon: Nylon is a polyamide. It also takes a very long time to biodegrade and can remain intact in the environment for decades to hundreds of years. However, newer bio-based nylons and engineered variants have been developed to be more biodegradable, but they are not yet widely used.

Acrylic: Acrylic fibers, made from polyacrylonitrile, are also resistant to biodegradation. They can persist in the environment for centuries, posing a significant environmental problem.

Spandex (Lycra®): Spandex is a polyurethane-based fiber known for its elasticity. Like other synthetic fibers, it takes decades or longer to break down and is highly resistant to microbial degradation.

This checklist is your go-to guide for making sure your claims about biodegradability are robust.

Be cautious of your language: Make sure your claims hold up to what they promise. Only use the term if you can specify how long or under what conditions, your textiles break down. And remember: In 10,000 years, everything biodegrades, but that’s not exactly what we’re hoping for, is it?

Know the conditions: Where does the biodegradation happen? In a landfill? In the customer's composting bin? A lot of materials (especially biodegradable plastics) only break down in specific conditions, like industrial composting facilities where the heat and moisture is controlled. So provide enough information about it.

Do you have a certificate or a proof? If a product is truly biodegradable, it should come with certifications or a test report that prove it. The standards you’re looking for include:

ISO Standards: ISO 17088 for compostable plastics, ISO 14855 for aerobic biodegradability in controlled composting conditions.

EN Standards: EN 13432 for packaging or EN 14995 for plastics, proving the material breaks down in industrial composting environments.

ASTM Standards: ASTM D6400 and ASTM D6868 are key certifications for compostable materials, especially for industrial use.

TÜV Austria OK Compost Home: In the rare case that your product can be composted at home, make sure to prove it with a certificate. And if not and your using “biodegradable” make sure your customers understand, that this doesn’t automatically mean they can burry their clothes in the ground.

Additionally, compostable certification bodies such as BPI (Biodegradable Products Institute) ensure that the product is safe for composting and breaks down completely without leaving toxic residue.

Provide testing data: Legitimate biodegradability claims should be backed by lab tests that specify the percentage of material broken down, the conditions, and the time frame. If you can provide the mass-loss rate over time – that’s even better!

Consider the end result: If a product is compostable, provide information on what it turns into. Compostable products should leave behind biomass, CO₂, and water—not harmful chemicals or microplastics.

Avoid "compostable" for synthetic materials: Be careful about this one because a compostable synthetic is very very rare and should be proven with extensive information.

Verify recyclable claims: In case you use claims about the recyclability of textiles the key rule is: The product must be made from one material (mono-material) to be recyclable in theory. Because complex textiles or blends of cotton and polyester or nylon and wool cannot be recycled into a usable textile on a large-scale at the moment. Though the future might look different.

Speak about the infrastructure: Most places don’t have the infrastructure to recycle fashion textiles. Does your brand have a reverse supply chain or provide clear guidance on how to return products for recycling? Remember: Only 1% of textiles are recycled into new textiles. The rest are downcycled into things like insulation or cleaning rags—if they’re lucky. So make sure you’re providing enough information about the “how” to customers.

Ditch polybag claims! If your products are delivered in a polybag, don’t claim the bag is recyclable. Polybags often slip through the grates of recycling facilities! So they’re not actually recycled - in practice.

Welcome to our pro section!

In this issue’s pro section, we cover all things biodegradable synthetics and dive into bio-based synthetics. Here’s the full list of what to expect:

Are biodegradable plastics the solution for our industry’s waste problem?

Bio-based vs. biodegradable plastics

Why bio-based plastics are not always biodegradable

Why integrating biodegradable plastics into recycling streams is not as easy as it may sound

Common claims about the biodegradability of synthetics and why they are wrong

While biodegradable plastics sound like better alternatives to traditional plastics, the truth is more complex, particularly in fashion and textiles. The potential for materials to be biodegradable is certainly an argument when discussing the environmental impact of products. The idea that small plastic particles can fully decompose in the environment is more reassuring than the accumulation of additional microplastics. However, (as with many many “solutions”) biodegradable synthetics don’t address the root problem and come with its own set of challenges.

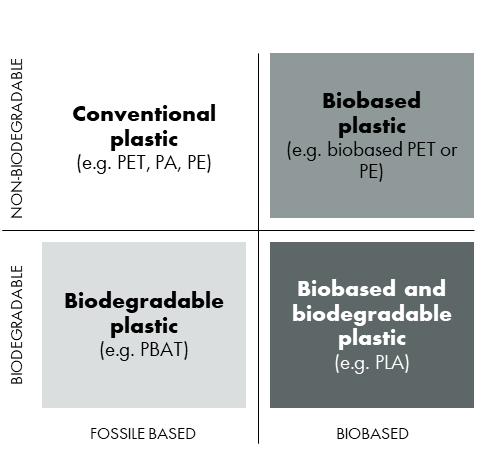

But before we dive deeper into biodegradable plastics, let’s get our definitions straight. Because bio-based and biodegradable plastics get mixed up a lot. And while they sound similar, they have entirely different meanings.

Bio-based vs. biodegradable plastics

Bio-based plastic refers to where the material comes from rather than what happens after it is used. Conventional plastics are largely oil-based. Bio-based plastics are made – either wholly or partly – from polymers drawn from renewable biological resources, such as vegetable oils, corn starch or sugar cane.

Biodegradable plastics can be broken down into carbon dioxide, water, and biomass by the natural action of microorganisms over an unspecified length of time and in undefined conditions. But biodegradable doesn't mean, that the plastic has to be bio-based. Also, fossil-based plastic types can biodegrade – just in a very slow process, and often leaving behind harmful residues.

Now that we know the difference between bio-based plastics and biodegradable plastics, we can tackle another widely spread misconception:

Why bio-based plastics are not always biodegradable

One of the most critical factors that determines whether a plastic is biodegradable is its chemical structure, not its origin. Traditional plastics, like polyethylene and polypropylene, consist of long, repeating chains of carbon atoms that are highly resistant to microbial attack. On the other hand, biodegradable plastics, such as PLA or PBAT, have chemical structures that microbes can break down under the right environmental conditions.

Bio-based plastics can be chemically identical to their petroleum-based counterparts, which means they don’t necessarily break down any faster in the environment. For example, polyethylene (PE) can be made from bio-ethanol sourced from sugarcane, but the resulting plastic is still the same chemically resistant, non-biodegradable material as fossil-based PE. The bio-based aspect of such plastics refers only to the feedstock and has no bearing on its end-of-life environmental impact.

Some bio-based plastics, like polylactic acid (PLA), are indeed biodegradable, but only under specific conditions. PLA, for instance, requires industrial composting facilities that operate at high temperatures (above 58°C) to break down effectively, which is rarely achievable in natural environments or home composting settings. So, while bio-based plastics reduce dependency on fossil fuels, they don't always address the end-of-life environmental concerns that biodegradable plastics claim to solve.7

What about oxo-degradable plastics?

Oxo-degradable plastic is often marketed as a biodegradable solution, but it comes with significant environmental concerns. Oxo-degradable plastics are typically made from conventional fossil-based plastics mixed with additives that promote fragmentation when exposed to sunlight and oxygen. However, these plastics don’t fully biodegrade into harmless substances. Instead, they break down into microplastics and pose severe risks to marine life, ecosystems, and human health. They’ve been heavily criticized by environmental organizations and phased out in some regions, including the European Union.

Why integrating biodegradable plastics into recycling streams is not as easy as it may sound

One of the most significant challenges in the circular economy is integrating biodegradable plastics into existing recycling systems. Biodegradable plastics often have different chemical structures than conventional plastics, which can complicate recycling processes. If biodegradable plastics are mistakenly introduced into recycling streams meant for traditional plastics like PET, they can contaminate batches of recycled materials, reducing their quality and economic value. As a result, many experts argue that biodegradability should only be prioritized when recycling is not a viable option, such as in certain packaging applications, single-use items, or textiles that are difficult to recycle at scale.

To better integrate biodegradable plastics into the circular economy, clear labeling and advanced sorting technologies are essential. Additionally, creating specialized recycling and composting streams for biodegradable materials is necessary to prevent cross-contamination and ensure these materials can be effectively processed at the end of their life.

What are the advantages of biodegradable plastics?

Biodegradability can be seen as a “better” cascade for thermal recovery. What does this mean? Under the principles of the circular economy, a product should primarily be reconsidered, and its longest possible use should be promoted. Only when a textile is no longer repairable or wearable should its material potential be utilized through mechanical recycling. When we truly reach the end of the material’s life, biodegradability can be seen as an option to keep the nutrients in the cycle instead of only using the thermal potential.

But we’re still far away from practically living this vision. And implementing it will require a significant systemic change – where manufacturers and the recycling industry coordinate more effectively.

Common claims about the biodegradability of synthetics and why they are wrong

Let’s jump right in:

"Biodegradable plastics decompose quickly and completely in nature."

Many biodegradable plastics require industrial composting facilities to break down effectively. In natural environments, they may decompose only partially or not at all and leave behind harmful residue.

"Oxo-degradable plastics are an eco-friendly solution."

Oxo-degradable plastics break down into smaller fragments but do not fully biodegrade. This can result in microplastic pollution, which is harmful to the environment.

"All biodegradable plastics are compostable."

Not all biodegradable plastics meet compostability standards. Compostable plastics must break down into non-toxic components under specific conditions, which many biodegradable plastics do not meet.

"Bio-based plastics are inherently better for the environment."

While bio-based plastics are derived from renewable resources, their environmental impact depends on their entire lifecycle, including production, use, and disposal. Some bio-based plastics can still generate significant pollution and require specific conditions to biodegrade.

"Biodegradable means it will degrade anywhere."

The term "biodegradable" can be misleading as it suggests universal degradation. However, many biodegradable plastics need controlled environments to decompose properly, which are not available everywhere.

🔹 Learned something in this issue? Share The Crisps with your friends and colleagues.

🔹 Like our content? Support us by sharing this issue on LinkedIn.

🔹 Got feedback or topics we should cover? Send us an email to thecrisps@substack.com

Disclaimer: The content and opinions presented in The Crisps newsletter are for informational purposes only and do not constitute legal, ethical, or professional advice. The Crisps does not endorse any specific brands or products mentioned in its content.

Haider, T. P., Volkova, A., Dong, W., Vollmer, I., & Wilts, H. (2021). Recent advancements in plastic packaging recycling: A mini-review. Frontiers in Sustainability, 2, Article 676282. Retrieved from https://www.researchgate.net/publication/354123944_Recent_Advancements_in_Plastic_Packaging_Recycling_A_Mini-Review

Hohenstein Laboratories. (n.d.). Biologische Abbaubarkeit [Biodegradability]. Hohenstein. Retrieved from https://www.hohenstein.de/de/kompetenz/nachhaltigkeit/biologische-abbaubarkeit

Hohenstein Laboratories. (n.d.). Biologische Abbaubarkeit [Biodegradability]. Hohenstein. Retrieved from https://www.hohenstein.de/de/kompetenz/nachhaltigkeit/biologische-abbaubarkeit

Hohenstein Laboratories. (n.d.). Biologische Abbaubarkeit [Biodegradability] (Factsheet). Retrieved from https://www.hohenstein.de/fileadmin/user_upload/Downloads/Factsheets/Factsheet_Bioabbaubarkeit_DE.pdf

Bao, H., Hong, Y., Yan, T., Xie, X., & Zeng, X. (2024). A systematic review of biodegradable materials in the textile and apparel industry. The Journal of The Textile Institute, 115(7), 1173-1192.

Lenzing AG. (2022). Biologische Abbaubarkeit von Lenzing generischen Fasern [Biodegradability of Lenzing generic fibers]. In Nachhaltigkeitsbericht 2022 [Sustainability report 2022]. Lenzing. Retrieved September 19, 2024, from https://reports.lenzing.com/nachhaltigkeitsbericht/2022/wesentliche-themen/kreislaufwirtschaft-ressourcen/biologische-abbaubarkeit-von-lenzing-generischen-fasern.html

Hottle, T. A., Bilec, M. M., & Landis, A. E. (2015). Bioplastics: Biobased plastics as renewable and/or biodegradable alternatives to petroplastics [Graphic]. Retrieved from https://www.researchgate.net/publication/276060634_Bioplastics_-_Biobased_plastics_as_renewable_andor_biodegradable_alternatives_to_petroplastics